With about six weeks of new operational data, the model was retrained, giving more accurate forecasts and enabling the microgrid to provide more value. Due to COVID-19, a site was commissioned into operation with a significantly different load profile from the data initially used to set up the model.

The initial insight from site modeling is used to set the control logic, and using machine learning and optimization results in better performance as more operational data becomes available.

We can also integrate new over-the-meter opportunities, presenting additional revenue opportunities. Updates of utility rates are automatically pushed out to the sites, allowing operation with the most recent information. Can the controls adapt if the microgrid or conditions change?ĪK: Yes, site changes can be easily incorporated into the model, for example the addition of more solar generation.

#Cleanspark forecast code

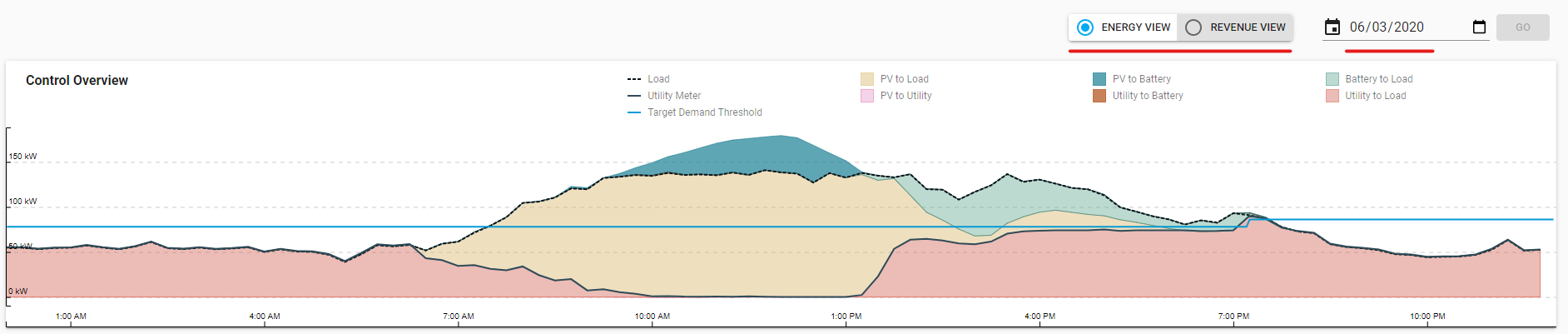

This eliminates potential problems with custom code and reduces setup costs. Our vendor agnostic library of equipment, combined with our approach of configuration-first controls, take site specific information and automatically set up the data and algorithms through a single API call. The path for optimal use of the assets to meet these objectives is plotted with high granularity, multiple times during each 15-minute interval.Īlso, CleanSpark’s commissioning process for the system has a high degree of automation, allowing us to avoid site specific custom coding. How much solar will be produced? What will the load profile look like? This information is combined with the site’s objectives, which could be as diverse as cost reductions, resiliency, and carbon neutrality. Patented forecasting and machine learning tools are used to build up an accurate picture of what is going to happen on a site over the coming 24 hours. How do CleanSpark’s controls differ to others?ĪK: CleanSpark’s controls are not just intelligent, but adaptive. Generally, intelligent control considers much more data, managing energy in a more sophisticated way to squeeze the most value out of the available resources. They also open up microgrids to continuously evolving over-the-meter opportunities. Intelligent controllers can evaluate weather forecasts, load conditions, and operational constraints to provide more effective control over time. These systems automatically adjust their behavior to meet the customer’s pre-set objectives, often based on analysis from a microgrid modeling tools. With today’s pace of change, a hard-coded, custom approach is no longer viable.Īs a result, we see the rise of intelligent controls systems. This approach will no longer be the most effective when utility time of use periods change or the customer adds on to their site, increasing load when solar isn’t available.

Take, for example, a solar only system, set to first satisfy existing load before pushing any excess over the meter. Any meaningful change requires the control code to be manually adjusted. There is a problem with this approach as the system runs, something within or around it will inevitably change. Amanda Kabak, chief technology officer and principal architect at CleanSparkĪmanda Kabak: Historically, controls systems have been implemented with custom code for specific pieces of equipment at a given site, designed to meet the site’s goals at that particular moment in time.

0 kommentar(er)

0 kommentar(er)